Biologically Enhanced Agricultural Management (BEAM)

Summary: Views of a regenerative grazier and climate hawk on Biologically Enhanced Agricultural Management, a system to boost soil organic carbon and improve soil health without chemical inputs. BEAM uses a low-tech composting method (static yet aerobic), the product of which sequesters carbon in soil by inoculating roots in ground with beneficial microbes (fungi > bacteria) rather than delivering carbon as would biochar. Comparing the mass of feedstock input to composting to the mass of carbon sequestered in treated soil, BEAM is several hundred times more efficacious than standard composting. It is 20-25 times as efficacious in carbon sequestration as most modes of “conservation agriculture” or improved grazing surveyed in meta-analyses of peer-reviewed studies. 150 million tonnes of vegetal and animal waste put through BEAM into the soil of all 150 million hectares (371 million acres) of U.S. cropland over twenty years could improve the soil greatly and by 2040 be drawing down 1.6 Gt C ( 5.9 Gt CO2)/yr, more than all U.S.A. annual CO2 emissions now. If BEAM proves as good as trials indicate, this country and the world would get a triple win by a WW II-mode home front project to compost clean waste and inoculate soil with the product: improved soil, more profit for farmers and substantial carbon drawdown. The project could begin on a small portion of US agricultural land and be incremented yearly. The methods could readily extend to a similar, ever-growing, proportion of global agricultural lands.

Introduction Prof. David C. Johnson, a molecular biologist at New Mexico State University, has a composting variant known as Biologically Enhanced Agricultural Management (BEAM) . The finished product, which he calls “inoculant,” is a crumbly solid with a high ratio of fungi to bacteria. Applied in small amounts, material like this can after a couple of years enable sequestration of far more carbon in soil per mass of raw material input than any other means of soil-tending except the peerless grazing + cropping program of Gabe Brown .

Johnson’s method is not the only way to make fertilizer that embeds or recruits mycorrhizal fungi to build carbon in soil. I have no data to compare its potential for carbon sequestration (hereafter, C-seq ) to that of one commercially-available counterpart (“MF”™ ) sold in the US. A U.S. – based maker of devices to prepare compost that stimulates microbial activity in soil reports that their solid product can be spread at a ton per 1-2 acres, about the same intensity as BEAM moist inoculant. A “tea” from the Aeromaster TE-500™ extractor (mfg Midwest Bio-Systems, Tampico IL) can turn that ton into a spray to treat 650 acres. What rate of C-seq or crop yield improvement either of these returns I don’t know. Nor do I know how the final product of BEAM compares in microbial populations to an Australian MF product (Nutri-Life Platform ™, YLAD Living Soils, NSW AU) also made with the Aeromaster.

So far as I can tell, commercial operations in AU and USA that make a bioactive soil amendment to mobilize mycorrhizal fungi in soil all turn their compost to keep it aerobic. It sounds as if some add a dash of mycorrhizal fungi to their inoculant just before it is to be applied to seeds or soil. Knowing today more about BEAM ‘s workings and performance than that of similar microbe-deploying processes I will confine my discussion to BEAM. Its low-tech management of clean waste makes BEAM potentially applicable at low cost to millions of acres worldwide to save soil and draw down carbon.

I can’t claim to understand BEAM fully, probably have some things wrong. Yet I believe it is monumentally important to soil and atmosphere health and am a voice for it.

|

Acronyms and notations used in text BEAM Biologically Enhanced Agricultural Management EtOH Ethanol F:B ratio of fungi to bacteria MCP Marin Carbon Project MF Mycorrhizal fungi NRCS Natural Resource and Conservation Service SBD Soil bulk density SOC Soil organic carbon content as % of soil SOM Soil organic matter as % of soil E+ 6 * 10 to the power of 6 ( = 1 million) = * 10^6 Gt billion metric tonnes = petagram (Pg) M mt million metric tonnes = teragram (Tg) mt metric ton = tonne = megagram (Mg) |

Acronyms used in text

BEAM materials and methods For a year since Don Wilkin told me about it I’ve admired David Johnson’s work from afar and exchanged e-mails and calls with him. For an introduction, click here to see Dr J. presenting in 2018; here to read an in-depth interview; here for an earlier interview; here to see a slide show; or here for a preprint of a report posted in 2015 citation David Johnson, Joe Ellington, Wesley Eaton Development of soil microbial communities for promoting sustainability in agriculture and a global carbon fix.

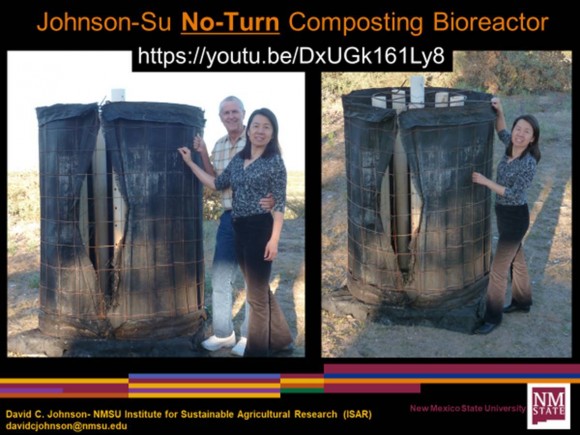

I see BEAM as two steps. First, prepare finished product (hereafter called BEAM inoculant) in a Johnson-Su bioreactor . Click here for pdf manual. One can be built for about $50 US of materials. Note: earthworms are necessary. Second, get BEAM inoculant, by one of a variety of methods described below, into soil that’s already growing plants, is being seeded, or has very recently been seeded.

BEAM needs no electricity or fuel combustion. It uses little water. Composting time, depending on location and season is 6-12 months, twelve preferred. It can be done on every continent but Antarctica. It can use manure (mixed with other waste) , pre or post-consumer food waste, waste from gardens and fields, tree leaves, barn litter, even wood chips (if small). BEAM does not demand “organic” inputs, though such must be preferable. Toxins like heavy metals and residual biocides (e.g. glyphosate) should be avoided, although many biocides are degraded by the microbes. Some feedstock (e.g. big leaves, spoiled hay) may need to be shredded or chopped. Earthworms are essential for the composting period after the early thermophilic phase.

BEAM is not on patent. The finished product is cheap to make. The Haggertys in Western Australia added 10 tonnes C /ha to their previously carbon-poor very dry soils with a one-time application of a seed coating for $30/ha. Their natural fertilizer was not made by Dr Johnson himself, but sounds to be on similar lines. I surmise they used product from Rhonda and Bill Daly, the founders of YLAD in New South Wales.. Click to view a microbial analysis on the YLAD “living compost” . In case that link does not work I have copied screen shots in the appendix. Remember, this analysis is not of Johnson’s inoculant, but of that made by a company in Australia with roughly similar methods and possibly similar output.

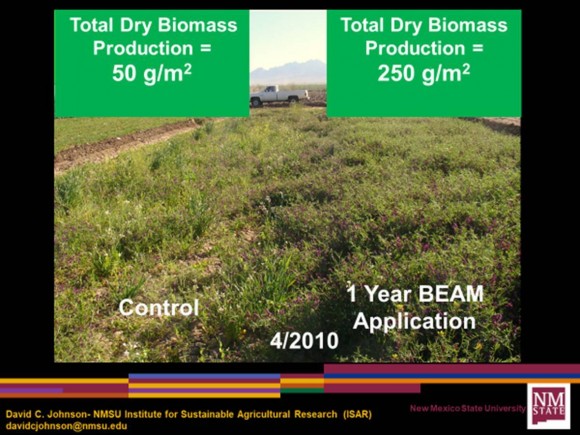

Dr Johnson reports C-seq rates from BEAM of 10.27 tonnes C/ha/yr when used on initially very low-SOC soil. This is 20-25 times higher than the mean rates of 0.4 to 0.5 tonnes C /ha/yr tabulated in two meta-analyses of “improved management” (Conant RT et al 2001; Garnett T et al 2017). It is 19 x the mean rate of 0.57 tonnes C/ ha/yr that West and Post ascertained from 67 long-term agricultural experiments around the world. (West and Post 2002.

Raw materials to fill Johnson-Su bioreactors are scarce in some dry places. One of the many advantages of BEAM, though, is that the final product, especially when diluted, is much more portable than traditional compost. How much more, is discussed below. Thus BEAM inoculant can be made where raw materials are abundant and shifted by small vehicle. From what the Haggertys described, a pickup truck (“ute”) can carry all the composting product that’s needed when mixed with water to significantly enhance carbon in the top 30 cm of 1500 acres. For the rest of this essay, however, I will be more conservative and say that 400 lb/acre of inoculant is needed to add 4.3 tonnes C to the soil of 1 acre 30 cms deep (Johnson, personal communication May 2018). That’s 1 lb/100 sf, a mere pinch as fertilizers usually go. To treat a hundred acres, however, needs twenty tons of INOCULANT. (800 fifty- pound bags) if the solid form is used..

The extraordinary potency of BEAM on a mass basis in boosting soil carbon is due to the high numbers of living micro-organisms (especially fungi) in the BEAM inoculant The BEAM composting process — relatively slow, static, passively aerated and high-moisture – promotes extensive fungal hyphae formation that is disrupted by conventional turning. In the video made at Chico State in 2018 at about minute 103 Johnson jokes that in the bio reactor the fungi “don’t find their furniture on the sidewalk.” Mycorrhizal fungi are not plentiful in the inoculant as it goes into the soil, though other fungi are, far out-populating bacteria. Once in the soil interacting with growing roots the inoculant makes mycorrhizal fungi proliferate. In the soil, the microbiota concentrated in the inoculant start sequestering carbon underground from CO2 captured above ground. The carbon in the inoculant itself is almost trivial

The role of mycorrhizal fungi in promoting plant health, stepping up photosynthesis and thus carbon sequestration in soil has been recognized for decades. One can buy bags of “MF” at Home Depot to use in the garden. This preparation has added minerals, it’s not pure compost. At retail price, it would cost $4000/ton. What I see as distinctive about Johnson’s BEAM system is that it’s simple enough to be do it yourself, but deployed on a grand scale would revolutionize agriculture. It is quite suitable to the developing world.

The amendment can be done in several ways. One is by scattering moist crumbles on soil surface at 400 lbs/acre. This can be done by hand on a small area. For a larger area, a slurry can be splattered; or, inoculant can be mixed with powdered biochar as a slurry then splattered. A larger area can be treated with a given quantity of inoculant by beating a chunk of it in water (1 kg/70 L water) , then straining the suspension. The extract is sprayed on foliage or dripped into a furrow with seeds. Another method is to bathe the seeds in a slurry, then plant them dry or wet-coated. Increased yield of above-ground plant matter is seen after only one year of BEAM.

Caution 1: Dr Johnson’s figures assume that all biomass grown (successive diverse- species legume-rich cover crops twice a year) is tilled back into the top few inches of soil for four years. Once BEAM has been in place for 4-5 years, tilling should cease for good. Every year or two foliar spray is applied at about 1 lb inoculant/acre diluted in the needed volume of water . Thus, for three or four years no cash crop from BEAM-treated ground can be harvested for take-away. This limits what proportion of her total cropland a farmer can commit to BEAM at any one time without expecting a temporary drop in cash crop yield.

On the other hand, most conventional farmers and ranchers have to buy synthetic fertilizer and biocides to get their usual yield. By starting BEAM on a piece of land, the operator forgoes the net profit on it, which is for most hardly enough and for many, in a bad year, a red negative unless salvaged by crop insurance. Furthermore, most farmers and ranchers will choose to treat their worst soil with BEAM before their better; there’s less that way to lose by not harvesting and a better marginal return on investment. Finally, when BEAM has matured on the ground held out of cash-cropping, yields should be so much better and input costs so much lower that the investment will pay off handsomely. The transition years remain a problem.

Caution 2 : The fungi and bacteria in the BEAM inoculant must interact with living roots. If ground is wholly bare, the inoculant should go in with seeds and at least a little water by each seed or should be injected into an already seeded furrow. The inoculant takes best when watered in by rain or irrigation.

Caution 3: Even when the mass of carbon in a volume of soil is increased substantially, say from x tonnes/ acre to 30 cm depth to 1.25x tonnes/acre t, the arithmetic difference year to year in measured SOC may be too small to be discernible given sampling variability The effect of BEAM should be validated by measuring above-ground mass of the crop year to year. This may need in the near future to be controlled for “CO2 fertilization.”

Practicality of BEAM compared to typical compost I did several sets of calculations about what mass of “ inoculant” delivers a specified mass of C-seq in top 30 cm of soil per unit area. By inoculant I mean the solid but kneadable material from the bioreactor after a complete cycle, before it is crumbled or suspended in water. All rates below are per year. Two sets are shown. Table 1 hypothesizes that C-seq in soil from using the liquid extract is 1/100th of 10.7 tonnes C/ha or 0.107 tonnes C/ha. I have no empiric basis for this number. Table 2 uses figures gleaned from reading interviews with Dr Johnson and corresponding with him [Lines 39 and 623 in the preprint read 10.27 tonnes The 10.7 value in these tables was imputed from line 468, but I saw no need to replace it as the results would be hardly different. ]

Table 1 0.107 tonnes C/ha/yr sequestered in soil using strained suspension in which 250 kg finished product are diluted so as to treat 250 ha

0.25 tonnes inoculant applied to 250 ha sequesters 0.107 tonnes C/ha

1 tonne inoculant applied to 1000 ha sequesters 0.107 tonnes C /ha

1 tonne inoculant applied to 2470 ac sequesters 0.0433 tonnes C/ac

0.0004 tonnes inoculant applied to 1 ac sequesters 0.0433 tonnes C/ac

C-seq yield of BEAM inoculant on a mass basis in this hypothetical scenario is .0433 tonnes C/ 0.0004 tonnes inoculant applied = 108

Table 2 10.7 tonnes C/ha/yr sequestered in soil by dusting surface foliage at 450 kg/ha ( = 400 lb/ac)

0.45 tonnes inoculant applied to 1 ha sequesters 10.7 tonnes C/ha

0.45 tonne inoculant applied to 1 ha sequesters 4.3 tonnes C/ac

0.45 tonne inoculant applied to 2.47 ac sequesters 4.3 tonnes C/ac

0.18 tonne inoculant applied to 1 ac sequesters 4.3 tonnes C/ac

C-seq yield of BEAM inoculant on a mass basis is 4.33 tonnes C/0.18 tonnes v applied = 24

Discussion A frequent knock on composting in general is that the mass of top dressing needed to cause sequestration of (say) 0.2 tons C/acre is so much it could not be used on millions of acres. This is true. A decent compost is 15 % C by weight with a C:N ratio of about 20:1 If C is 15% (i.e. 300 lb /ton), just to spread 0.2 t C/ac requires applying 400/300 = 1.35 tons of top dressing dry weight per acre. Much more would be needed to set the stage for actually sequestering 0.2 t/ac to 30 cm deep in soil.

It’s painfully clear, then, that a great deal of raw material would be to prepare a compost that would boost soil organic carbon content in a large area even in the most important top four inches. The esteemed Marin Carbon Project (Ryals and Silver 2013) was not designed to measure carbon sequestration in soil but, rather, to see if compost could restore degraded grazing land [ Note: it can] I got from Toensmeier’s Appendix C that 2.1-4.7 t C/ha/yr were sequestered over four years. [To my dismay I could not understand from the article how Toensmeier calculated the range of the rate estimate, but that’s my problem.]

In the MCP finished compost from municipal waste was applied to soil at 70 t dm/ha . It’s a safe bet that at least 150 tons of wet raw material had to be trucked, windrowed and periodically turned. The Cornell Waste Management Project composting method, for example, got about 1 ton of finished compost for every 5 tons of fresh material. (Schwarz and Bonhotal 2018). When many tons of finished amendment /ha are needed, the process cannot be applied to many millions of acres/year.

Let’s compare the C-seq in soil observed in the MCP to that reached by BEAM in respect to mass of final product applied to soil, using Table 2. Remember, the MCP figure is a secondary finding . This was not the research objective.

MCP 28 tonnes of finished compost applied to 1 acre with plant mass partly ingested, not all put back into soil sequesters 2.1 to 4.7 tons C/ha/yr = 0.8 to 1.9 t/ac . The mid-range is 1.4 tons C/ac/yr The C-seq yield is 1.4 t / 28 t = .05 tonnes C sequestered/tonne dm finished product applied/acre (these may be short tons but no matter; it’s the ratio that matters)

Johnson-Su compost yield with all plant mass put back into soil is 4.33 tonnes C /0.18 tonne applied = 23.9 tonnes C sequestered/ac /tonne INOCULANT applied/ac

NB: The C-seq in soil yield of BEAM is 23.9/0.05 = 478 times greater than MCP weight for weight of product applied.

Another dig against amending soil with compost made on a farm or ranch (and thus likely using at least some manure) to restore C-depleted soils is that it is robbing Peter to pay Paul, moving carbon from one spot on the earth to another. This is true if the soil out of which the carbon came before composting does not get it all back.

Say the herd ate a ton of carbon from the herbage of two acres in the west pasture and the compost or stockpiled litter spread back on did not return a ton of C to the pasture. There has been a net loss of C unless improved grazing practice has caused C-seq despite removal of carbon. Moreover, flinging a ton of C onto the sward of the west pasture does not put all that C far enough into the soil to be sequestered.

In BEAM, the transfer of carbon from point A to point B counts for little, because the active agent of carbon sequestration in soil with BEAM is not carbon but micro-organisms. This makes it relatively easy to restore by biological activity to a plot or field carbon that was taken from it by harvesting a crop. Based on figures Dr Johnson gave me in an e-mail in early 2018, if 1800 lb (818 kg) of wet-weight crop residue from two acres of cropland are composted, the inoculant yield is 700-1000 lb, let’s say 800 lb ( = 364 kg ) . This is enough spread at 400 lb ( = 182 kg) /acre on those same two acres, to sequester 4.33 tonnes C/ac/yr.. Say the dry weight of the crop residue is 15% of 818 kg , of which about 48% is carbon.. Thus about 56 kg of C went into the reactor from those two acres, while each of the two gains 4.3 tonnes C/yr. Good return on carbon investment !

Spreading the wealth of BEAM According to FAO http://www.fao.org/faostat/ the USA has about 150 million ha of “arable” land suitable for cultivation. The world has about 1.4 billion ha of arable land, most of which could use a higher soil organic carbon level. To treat all US arable land with a dusting of 400 lb BEAM inoculant /ac (= 449 kg/ha) would take 67.4 million tonnes. To prepare that amount would call for 67.4 * (818/364) = 151.5 million tonnes of vegetal or animal waste feedstock to be collected and put into about 190 million bioreactors, each tended with a minute’s daily labor for a year.

Every hectare treated would have to be put into eight successive two/year cover crops for four years, with no two exactly alike. Each crop would be crushed and lightly tilled into the top four inches of soil. If ten per cent of USA arable land went into the program per year, it would take fourteen years to finish. This seems a big task, but compare it to another fairly recent enterprise, corn ethanol.

The USA grows and delivers about 5 billion bu (140 million tons) of shelled corn/year for making ethanol and about an equal tonnage of associated corn stover not used in that process. In 2011 (the figure is probably lower now) 20.9 million acres of cropland were dedicated to corn for ethanol. (Mumm et al, 2014) The ethanol thus produced is about 365 million bbl/yr or 45 million metric tons. The corn ethanol life cycle is far from carbon-neutral. Production facilities alone in 2014 emitted 18 M mt CO2

Sequestration to 30 cm depth of 10.7 tonnes C/ha/yr on 150 million ha approaches (at 0.26%/yr) the global 4per1000 initiative objective for annual SOC improvement and also draws out of the air 1.605 million tonnes C/yr = 1.6 Gt C/yr. See Table 1 col F below. This is 16 % of global carbon emissions for which humans are responsible. [I disdain the malformed neologism “anthropogenic” though it is now accepted by everyone else.] It is more than the annual CO2 emissions of the USA. (see Table 2)

Figure 1 below compares actual net annual carbon emissions just from facilities that produced corn ethanol (not full life cycle) to potential net annual emissions associated with BEAM on 150 M ha. The tonnage of raw material is about the same for both, about 150 M mt. Only shelled corn is counted, which understates the tonnage of corn appropriated for EtOH by about half. I won’t consider here that distiller’s grain from the process is used as animal feed. The BEAM value of minus 1,600 M mt is potential, not actual .

Figure 1. Net potential annual CO2 emissions from BEAM on 150 M ha compared to net actual emissions from facilities that produced corn ethanol. Neither is a complete Life Cycle Assessment.

|

A |

B |

C |

D |

E |

F |

G |

|

|

million ha |

INOCULANT mt/ha |

RM M mt |

M mt INOCULANT appl |

seq Mmt C |

seq Gt C |

seq Gt CO2e |

|

|

1 |

150 |

0.449 |

151.5 |

67.4 |

1605 |

1.605 |

5.89 |

|

2 |

1500 |

0.449 |

1515 |

674 |

16050 |

16.05 |

58.9 |

Table 1. Amounts of raw material (RM) and BEAM finished product (INOCULANT) needed to sequester in soil a specified mass of C (in gigatons = Gt) on a specified area of land.

Col A land area to be treated

Col B metric tons of finished product BEAM to be applied /ha

Col C metric tons RM (raw material) needed to make the INOCULANT/ha in col B C= D *818/364

Col D total application of INOCULANT in million metric tons over all hectares D = A* B

Col E total carbon sequestered in soil over all treated hectares in million metric tons E = A* 10.7

Col F total carbon sequestered in soil over all treated hectares in billion metric tons (Gt)

Col G carbon in col F transformed into CO2

Line 1 is USA cropland area Line 2 is world

|

Global Gt/yr |

USA Gt/yr |

|

|

all GHG Gt CO2-e |

50.1 |

6.5 |

|

CO2 only Gt CO2 |

37.1 |

5.3 |

|

CO2 Gt C |

10.1 |

1.45 |

Table 2. Gross (I think) GHG emissions for globe and USA for all GHG and for CO2 only. Guesstimates and predictions for 2018 from various sources

Different figures can be put into Table 1 to see new scenarios. The BEAM treatment of just 15 M ha of US arable land (10% of total) would require composting only about 15 M mt of waste to ultimately sequester 0.16 Gt C/yr , That mass would almost offset all USA ag emissions (aprox 0.18 Gt C/yr ). Alternatively, more land could be treated.

If US grazing land, estimated by NRCS to be 213 million ha, were encompassed as well as all arable land, 363 E +6 ha would be available. This would require 367 M mt raw feedstock but would sequester 3.88 Gt C, more than half of total US GHG emissions as CO2-e. Note that the effect of Johnson’s inoculant on perennial grasslands could be less than on cropland because the inoculant might not get as close to roots as fast when scattered or sprayed as when touching the seed. Moreover, it would be imprudent to treat all perennial grass and forbs like a succession of cover crops with serial shallow tilling. On the other hand, spraying pasture just before a brief rotation of trampling defecating grazers might be a big plus. Another unknown.

A liquid extract of the inoculant coated onto seeds or spot injected by seeds at planting could magnify its effect so that only a few million tonnes, carefully applied, might over fourteen years suffice to sequester 10.7 tonnes C/ha/year on 150 M ha . A liquid (Nutri-Life Platform™) made by a method that resembles Johnson’s is advertised to benefit soil and plants when seed is coated with only 50 grams/ha. I have no data on C-sequestration attributed specifically to this material, but it may be the seed coating that the Haggertys stated added 10 tonnes of C to their soil at very low cost/ha ($22 USA).

Conclusions If C-seq in soil via bioactive soil amendments like the BEAM system on 150 M ha did nothing for soil quality, “only” drawing down 16% of global CO2 emissions/yr, it would be cost-effective in materials and job-creating compared to high-tech CCS methods.

If C-seq in soil via via bioactive soil amendments on 150 M ha did nothing to remove CO2 from the atmosphere, but increased SOC by 0.26%/year, it would save our soils and water from impending ruin, remembering that water is damaged by nitrate runoff .

Thus, C-seq in soil via via bioactive soil amendments on 150 M ha has the potential for enormous good on both the above fronts without risk of harm except short rotation of some land out of chemically-dependent cash-cropping. This is a blessing, undisguised but unrecognized. Our country sees nothing amiss in processing several hundred million tons of good field corn to make 45 million tons of ethanol that’s distilled with energy, transported by rail and combusted into CO2. This is the will of lobbies.

Think back to the line above “The treatment of just 15 M ha of US arable land (10% of total) would sequester 0.16 Gt C, almost negating all ag emissions (aprox 0.18 Gt C).” Compare that to the manufacture of corn ethanol, which in 2011 used 8.5 Mha and has according to USDA slightly more than half the GHG intensity of gasoline in its life cycle, no small amount. Which is a better idea for our country ? Support a biofuel industry on 5% of US arable land that enables increasing fossil fuel combustion OR start 10% of arable land per year on a low-cost path that over 10-20 years can restore failing soils, decrease dependence on nitrogen fertilizers and almost negate agricultural GHGs?

Just asking.

________________________

End-note about units. Readers are likely annoyed or bewildered by what seem capricious jumps from metric to standard units even allowing hybrids like “ tonnes/acre/” Read carefully, make notes. Note also that this entire essay treats elemental carbon, not CO2. There are many chances for confusion especially in memory, when some writers specify CO2 and others C. It’s easy to read somewhere about a C-seq rate of (say) “ 1.5 tonnes CO2/ha/yr” (depth not even specified) and recall it later as 1.5 tons C/ha/yr or worse yet 1.5 tons C/acre/yr or 1.5 tons CO2/ac/yr . Many permutations.

References not given as hyperlinks in the text are below

Conant RT, Paustian K and Elliott ET Ecol Applications 11 no 2 : 343-355 2001

Garnett Tara et al “Grazed and Confused?” Food Climate Research Network 2017

Johnson, David, Joe Ellington, Wesley Eaton Development of soil microbial communities for promoting sustainability in agriculture and a global carbon fix. https://peerj.com/preprints/789v1.pdf

Ryals R and Silver W Ecol Applic 23: no.:46-59 2013

Schwarz M and Bonhotal J Compost Science and Utilization vol 26 issue 2 pp 128-143 2018

West TO and Post WM. Soil Science Society of America Journal vol 66: 1930-1946, 2002

Toensmeier E. The Carbon Farming Solution. Chelsea Green, 2016

Written by Stephen Q. Shafer MD MA MPH Saugerties NY 12477 Permission to quote is hereby granted so long as the permalink is cited. Photos of Dr and Mrs Johnson and of the control and BEAM plots used here are by permission of Dr Johnson and cannot be reproduced without his permission.